Chinese Manufacturer of Jewelry

Churinga is one of the top manufacturers of jewelry in China. The jewelry factory provides a full range of high-level jewelry at a reasonable price. This jewelry could go with some precious semi-precious stones& natural stones. We specialize in Custom Jewelry for our clients, 3D or drawing pictures, and an idea with reference pictures; We could make them come true. The products include 925 silver jewelry, 316L stainless steel jewelry, and copper jewelry. We also provide jewelry wholesale for starting brands with the mold and stocks we have.

Jewelry Custom Styles

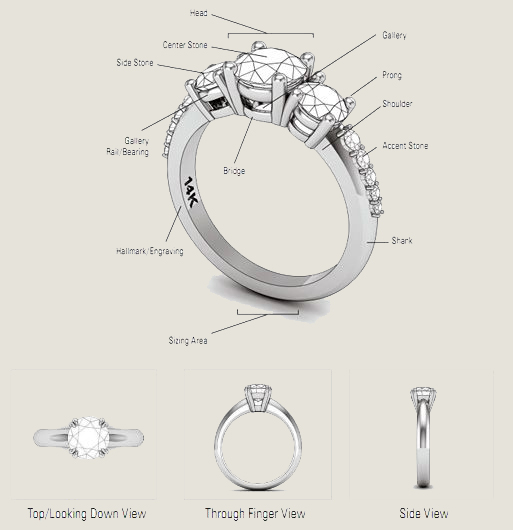

Your jewelry design ideas, pictures or sketches

3D Rendering

Within 3-7 days, 3D design confirmation

Samples Production

Within 10-20 days we’ll finish the jewelry sample production

Confirm Samples

Reconfirm whether the sample needs to be modified

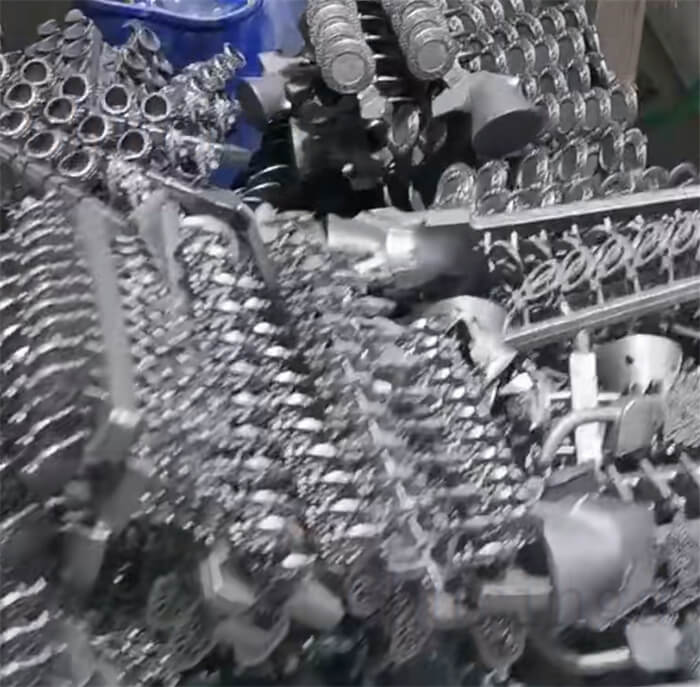

Mass Production

Our monthly output is about 200,000 to 250,000 pieces

JEWELRY OEM & ODM

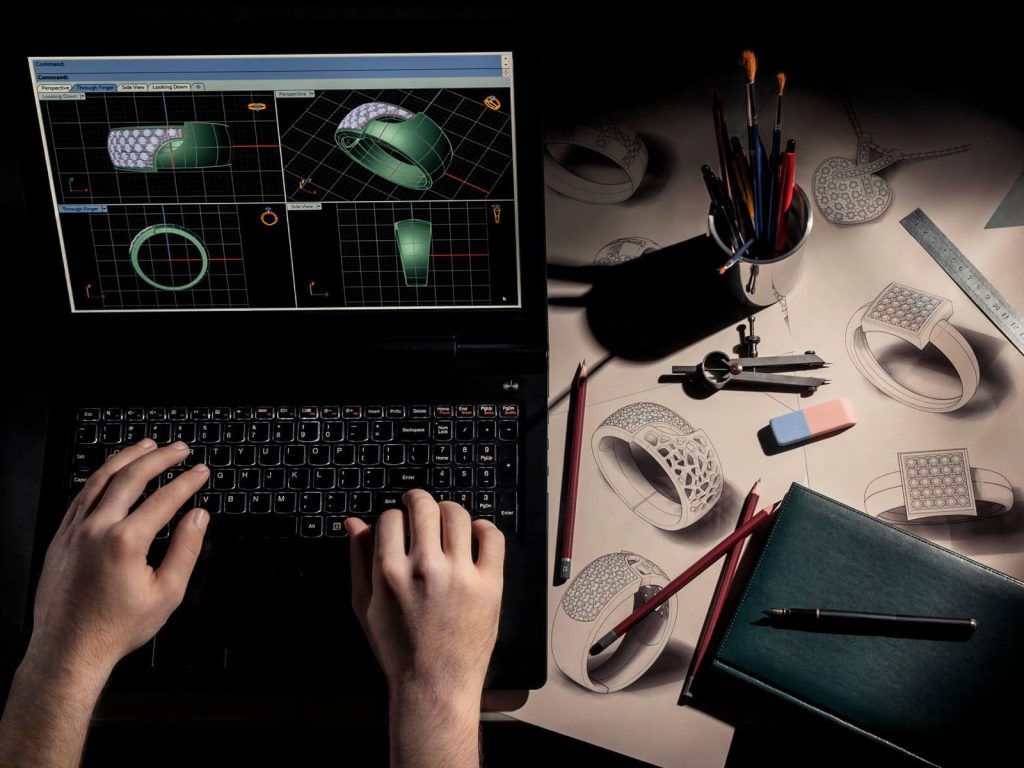

As an OEM jewelry supplier, Churinga jewelry factory has successfully handled thousands of different jewelry custom designs, During these years, We have:

- Custom & OEM company brand products

- 16 years of jewelry making experience

- Provide your ideas & sketches and related materials

- We have a strong production chain

- 3D jewelry designer and hand engraver

- Mass production of different styles of jewelry

- Strict quality control

- Explore new product development together

Jewelry Wholesale Supplier

As a private label jewelry manufacturer and wholesale stainless steel jewelry manufacturer & supplier, Churinga has our own jewelry factory. Therefore, the starting batch is very low the delivery time is fast, your cost is reduced, and save time.

Jewelry manufacturers china, we mainly wholesale stainless steel jewelry, Stainless Steel Rings Wholesale, Stainless Steel Earrings wholesale, Stainless Steel Bracelets wholesale, Stainless Steel Necklaces wholesale, Stainless Steel Pendants wholesale, and other silver jewelry wholesale.

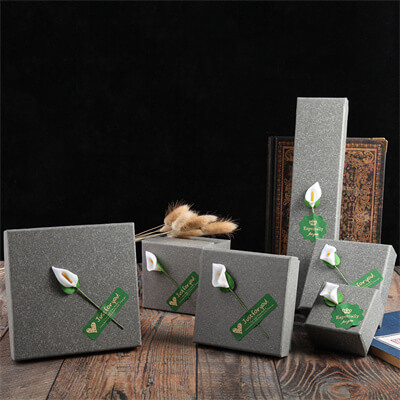

Provide custom jewelry boxes

Churinga in order to consider the transportation of the products, we adopt simple packaging. In order not to affect the delivery time, if you need the brand logo or special packaging, please tell us in advance, and we will help customize jewelry the brand logo, and special packaging materials for you.

Designed And Jewelry Manufactured By Us,Inspired By You.

Ready To Design With Us?